SSAB is a highly-specialized global steel company driven by close relationships with our customers. SSAB develops high-strength steels and provides services for better performance and sustainability.

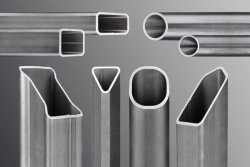

The company is a leading producer on the global market for Advanced High-Strength Steels (AHSS) and Quenched & Tempered Steels (Q&T), strip, plate and tube products, as well as construction solutions. SSAB’s steels and services help to make end products lighter and increase their strength and lifespan.

SSAB has a cost-efficient and flexible production system. SSAB’s production plants in Sweden, Finland and the US have an annual steel production capacity of approximately 8.8 million tonnes. The company also has capacity to process and finish various steel products in China, Brazil and many other countries. In Sweden and Finland, production is integrated into a blast furnace process. In the US, electric arc furnaces are used for a scrap-based production process.

SSAB has been at the forefront of sustainability in many ways. With confidence deriving from our traditions, we now strive to do even more. Our plan is to eliminate all of our CO2 emissions by 2045.